For nearly 130 years, GIW has produced and delivered the world’s best pumps to customers across a variety of industries and applications. Our oldest and most versatile pump is the LSA: the grandfather of all other pumps we offer. While our customers are more than familiar with its capabilities, some may not know about its legacy. Today, we highlight the LSA pump to show you exactly why it’s been the best pump in the game for over a century.

Design of the LSA pump

The company we all know today as KSB GIW, Inc. began in 1891 as a small, privately owned foundry and machine shop located in Augusta, GA. It was incorporated as Georgia Iron Works in May of 1892, primarily as a production facility of "High Grade Heavy Saw Mill Machinery" and ornamental iron. In 1914, Georgia Iron Works began manufacturing spare parts for the solids-handling pumps used in the Florida phosphate industry. Soon thereafter, GIW began designing and manufacturing their own slurry pumps to meet their phosphate customers’ growing demands—this was the beginnings of the LSA pump.

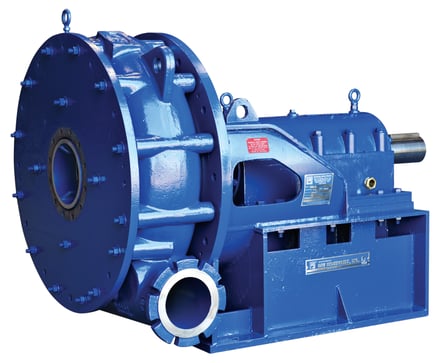

A lot has changed since then, but one thing that has remained the same is the LSA’s design philosophy. The LSA is a premium-design, hard iron pump built for a long wear life and suited for the most severe slurries. It has a single-wall construction with a heavy section, hard-metal wet end. The robust, LSA-style cartridge bearing assembly works in tandem with the wet end to provide maximum reliability and easy maintenance.

Best of all, the LSA is highly modular and has interchangeable parts. Operators can select metal or optional elastomer wear parts paired with various sealing options, depending on their application. This easy swap-in-swap-out feature simplifies maintenance and allows our customers to vary their operating conditions at low cost.

LSA applications include ash removal, dredging, energy, hard rock, and materials mining. However, customers have found success with the LSA in environmental cleanup, dewatering, pulp and paper transfer, food processing, and coke/resin pumping as well. It just goes to show that the LSA is one of the most versatile pumps on the market.

A performance powerhouse

The LSA’s technical specifications meet or exceed those of competing pumps. LSA pumps can transport slurry up to 350 feet (105 m) of head at flow rates over 110,000 gpm (25,000 m3/h). They can handle pressures up to 715 psi (up to 50 bar) and withstand temperatures up to 250 degrees Fahrenheit (120 degrees Celsius). Customers can choose an impeller with four vanes or three for larger solids; either way, the impeller can withstand wear in highly abrasive conditions.

Once the parts have reached the desired run cycle, replacement is made easier by features and tools offered by KSB GIW, Inc. An impeller release ring is available on several models and helps increase the ease and safety of an impeller change out. There is an optional Impeller Release Ring Tool along with several lifting device options also available.

Customers have the option of using various hydraulic designs and materials for the same mechanical end without sacrificing wear life or efficiency. Most importantly, they have their choice of pumps in the LSA series that fit the best type, size, and operation speed for their system.

Expert applications

Our core design team in Engineering works with our customers to design robust solutions that solve their pumping problems and improve performance. These real-world challenges often lead to some of our best product innovations. Some offspring pumps from the LSA exist solely due to a specific application, like the DWD Dredge pump we made for Hua Hai in China.

At the GIW Hydraulic Lab, our Engineering personnel test full-size pumps to validate their performance, run different slurry types to quantify performance in different applications, and test the wear potential of many materials on parts. They also train operators and maintenance staff in our annual courses!

Other than some slight modifications — and a spin-off, the MDX — the LSA pump has not changed much over the years. Thanks to its versatility and excellent design, our customers can rely on the LSA to tackle nearly any situation. It has proven time and again that sometimes you can’t do better than the classics.