The standard seal arrangement for KSB GIW, Inc. LSA pumps is the stuffing box. The water supply for this seal cools and lubricates the packing. The seal water enters the stuffing box through two inlet ports and is distributed around the shaft sleeve by the lantern ring. The water flows between the stationary packaging and the rotating shaft sleeve in two directions. Some water flows forward and enters the pump and some water flows the opposite direction and exits the stuffing box.

Seal water quality is always an issue. It doesn’t have to be drinking-water quality, but it should:

- Be non-aggressive

- Have a neutral pH

- Not form deposits

- Contain solids less than 2500 ppm and 50 microns

- Be delivered at a consistent 10 psi over discharge pressure

Once you have the right quality, how much seal water do you really need?

The type of seal determines the amount of seal water required. KSB GIW, Inc. LSA pumps have three types of stuffing box seals:

The type of seal determines the amount of seal water required. KSB GIW, Inc. LSA pumps have three types of stuffing box seals:

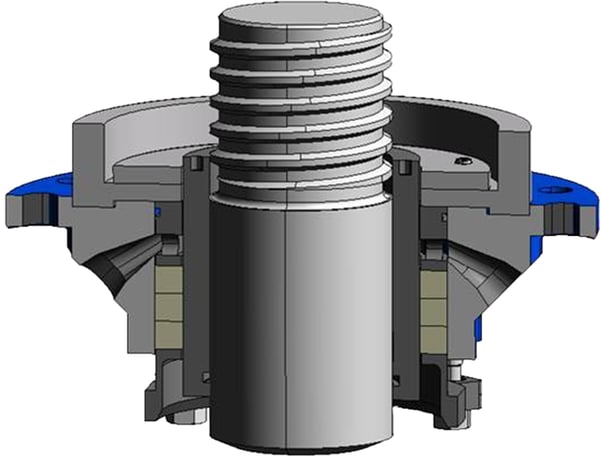

- Throat Bushing — This is the standard stuffing box seal furnished with LSA pumps. It doesn’t require a great deal of seal water, and it’s easy to maintain.

- SpiralTracTM — If you want to introduce less water into your product, we recommend this type of seal. Its patented design reduces the flow rate going into the pump by 30-40% over the standard Throat Bushing design.

- KE Low Flow — To nearly eliminate dilution in your product, this seal uses the least amount of seal water.

You can easily determine your water requirements by referring to Section 9 in the KSB GIW, Inc. LSA Maintenance Manual. The manual provides an easy reference chart that tells you exactly the amount of water you need to have available for your particular stuffing box and application.

When you review the water requirements chart, you’ll quickly see how much your water requirement is reduced by using the KE Low Flow seal. So why wouldn’t you want the KE Low Flow for every application?

As with any choice, there are pros and cons when you’re deciding which seal is best for your application. The KE Low Flow seal, for example, does require less water, but also needs more maintenance and is less flexible in handling wide swings in operating pressure.

To get accurate recommendations for best practices in optimizing your pump operations and maintenance, be sure to contact your GIW representative.