Centrifugal pumps are fairly robust pieces of equipment and generally deliver the intended results when sized and installed properly. But sometimes, if all factors aren’t considered, one might find themselves with a misbehaving pump (i.e., one that vibrates excessively, fails to deliver the anticipated flow, or even suffers severe damage). One possible cause is air entrainment in the liquid being pumped.

It goes without saying that a pump designed to handle liquids — especially solids-laden liquids — is not going to make a good air pump. In fact, it’s well documented that just 5% air by volume can reduce the capacity of a centrifugal pump by 50%. And while no one intentionally sets out do this, in the real world sometimes “things happen” despite our best efforts and may need to be remedied.

The “obvious” solution is to speed the pump up or install a larger diameter impeller. While this might solve the problem in the short term, it is often accompanied by other side effects, like bearing failures, or in the case of slurry pumps handling abrasive particulates, greatly increased wear. Since wear is a cubic function of speed, one might reasonably expect a 73% increase in slurry pump wear rate with a speed increase of only 20% (i.e., 1.2 raised to the third power is 1.73). Assuming your process doesn’t produce air or gaseous vapors, let’s look at two common causes.

Submergence

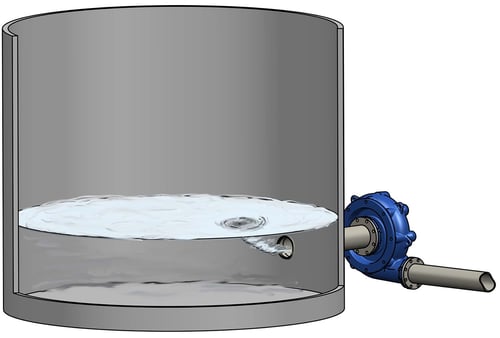

We are all familiar with the phenomenon of water spinning or “vortexing” as it goes down a drain. Submergence, or rather the lack of sufficient submergence, can manifest itself as a vortex coming up from the suction piping inlet to the free surface of the liquid in a tank. This vortex has an “air core” which allows air to be dragged directly into the suction of a pump. These air bubbles displace liquid in the suction line that should be entering the pump, which reduces pump capacity.

Bubbles also migrate inside the pump to the area of lowest pressure (e.g., the eye of the impeller) where they obstruct the entrance of additional liquid entering the pump and reduce flow and efficiency even further. At exceptionally low concentrations of air, the pump can often flush away the accumulating air. But if the air accumulates faster than it can be flushed away, the air in the eye of the impeller will block new liquid from entering. This phenomenon is called airlock. Airlock is not always gradual. It can manifest suddenly once the requisite amount of air is present, and it adds operational instability on top of high losses.

If one can physically see a vortex inside their supply tank, the simplest solution is to increase the liquid level inside the tank. The energy of the vortex might then be viscously dissipated before it reaches the free surface of the liquid inside the tank thus closing off this avenue for air to enter the pump. Another possible remedy is a downturned suction bell inside the tank. Each solution comes with its own pros and cons to consider.

Air from free surfaces

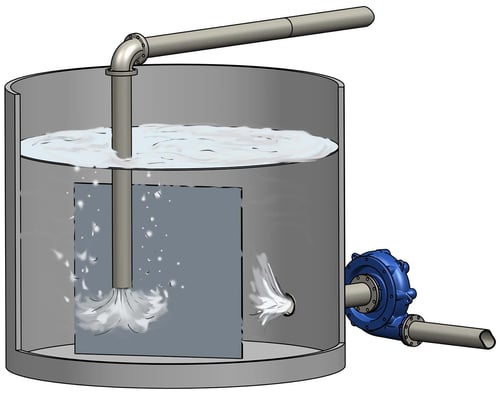

More common but less obvious causes of air entrainment include poor piping layout and operating practices that introduce air at free surfaces. Consider the illustration below.

In this example, several physical characteristics combine to aggravate the situation:

- The inlet piping to the tank is located so it discharges directly over the top of where the pump takes its suction.

- The liquid falls a relatively long distance before it impacts the free surface of the liquid inside the tank. Upon impact the liquid draws air down from the free surface deeply into the liquid already present inside the tank.

- The liquid level is exceptionally low in the tank, further increasing the distance, and thus the impact energy, the incoming liquid must fall before it mixes with the liquid already inside the tank. More impact energy correlates with a greater amount of air drawn down from the free surface.

The final illustration shows possible solutions to this source of air entrainment.

- Move the tank inlet pipe to a point as far away as possible from where the pump takes its suction.

- Extend the inlet pipe and increase the liquid level so the incoming liquid enters below the free surface of the liquid in the tank. Increasing the liquid level is something plant operators are often reluctant to do because no one wants to be the operator who let the process overflow. Special attention is necessary to monitor and prevent such spills.

- Severe cases might benefit from a baffle inside the tank. The purpose of the baffle is to guide entrained air back to the surface and away from the suction piping leading to the pump.

Of course, this short article can’t cover all causes of, or solutions to, air entrainment problems. But by simply being aware that air is detrimental to centrifugal pump performance, the piping designer, plant operator, or plant engineer is better equipped to prevent, identify, and remedy situations in which pumps are not producing the flows their curves say they should as well as potential sources of wear and mechanical failure.