In the long run, nothing is as crucial to slurry pump design as wear life. On any given day, countless particles and chemicals within slurry can wear down pump parts and negatively affect performance. The two phenomena most responsible for everyday wear impact on pump part wear life are corrosion and abrasion. But what are they — and what causes them?

Corrosion and abrasion 101

Corrosion occurs when chemicals within slurry interact with the materials that comprise pumps and dissolve them over time. Abrasion, on the other hand, occurs when hard particles — like sand or gravel — rub against solid surfaces and wear them down. Both types of wear can hurt pump performance. It’s important to understand what causes abrasion and corrosion so that you can prevent premature wearing of your pump parts.

Fortunately, KSB GIW, Inc. has developed a range of parts custom-built to resist both corrosion and abrasion. They’ve also created tools to help mine operators select the right parts for their slurry pumping needs. When it comes to part selection, however, there’s a lot to consider: Are the particles in the slurry especially large or sharp? Is the liquid in the slurry acidic? How much hydraulic pressure is necessary to transport the slurry?

That’s where GIW’s SLYSEL software comes in. GIW’s patented pump selection software helps users determine the right KSB GIW, Inc. pump for any mining environment to maximize corrosion and abrasion resistance and extend pump wear life. The software’s wear material selection is based on a few factors:

- Solid size, shape, and hardness, which impact abrasion.

- Slurry temperature, pH, and chemical content, which impact corrosion.

- Impeller speed, which determines how much energy pumps impart to slurry.

Pump materials

With those factors in mind, it’s time to consider the materials that make up a pump. Hard irons — such as white cast iron — and martensitic steels are used most often in slurry pumps. These offer considerably higher resistance than ordinary steel. GIW’s Gasite® white irons are free of graphite, so they’re best for slurries with large particles as well as high temperatures and pH. These metals are superior to carbon and low-alloy steels, which are not as corrosion- and abrasion-resistant. In fact, hard irons and martensitic steels are especially effective for such applications as oil sands mining.On the other hand, soft liners like elastomers are effective for small particles, low temperatures, and low pH. Additionally, ceramic wear parts are useful when slurries are especially abrasive and pumps must resist extreme wear in low-pressure applications. When used alongside tough metal parts, these liners and specialized wear parts help slurry pumps perform more efficiently and extend pump life.

The materials used in slurry pumps largely depend on application conditions and the degree of corrosion or abrasion each pump must resist. GIW recommends a few slurry pumps based on their applications:

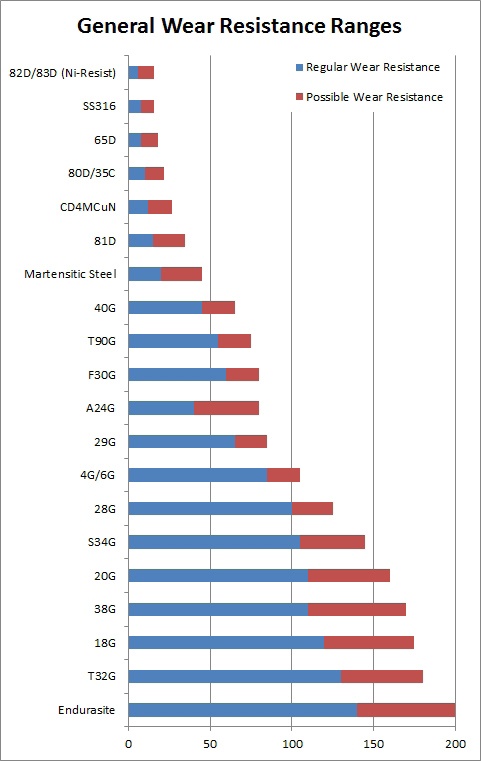

- Abrasion resistance — Endurasite, T32G, and 18G alloys offer superior abrasion resistance. The KSB GIW, Inc. LCC®, TBC/WBC High Pressure®, and MDX® pumps are all recognized for high performance and low maintenance — even with aggressively abrasive slurries and severe conditions.

- Corrosion resistance — The Gasite® T90G alloy offers excellent corrosion resistance. The KSB GIW, Inc. LCV Heavy Duty Vertical®, LCC®, and LSA® pumps come highly recommended thanks to their use of highly corrosion-resistant alloys.

- Corrosion and abrasion resistance — Several GIW alloys offer the best of both worlds. Many high-alloy martensitic steels like 18CS, HH, and HK alloys are corrosion- and abrasion-resistant. Pumps like the KSB GIW, Inc. Mega Slurry Pump® are especially effective. GIW recommends these for slurries with coarse or fine particles as well as slurries that are severely abrasive, corrosive, or both.

When it comes to GIW’s range of pump and material offerings, this list is only the tip of the iceberg. The GIW SLYSEL selection software provides more in-depth and customized pump options for a variety of industries, including mining, energy, manufacturing, and building services. This comprehensive user-friendly tool can help you determine the optimal solution for your projects and maximize your slurry pump wear life.