Pump performance curves help slurry pump owners and operators select their pumps and operate them optimally. How can pump owners calculate their slurry performance curves, and should they be able to read water curves manually?

Water curves

“Water curves give the pump performance at various pump speeds,” KSB GIW, Inc. Senior Hydraulic Design Engineer John Furlan explained.

So, by first reading water curves, operators can select the proper pumps for their unique slurry applications.

“We talk about water curves because slurry curves would change depending on what slurry you had going through the pump. It’s convenient to use water curves and then derate those water curves to calculate what the slurry performance would be,” Furlan said.

Potential problems

Without being able to read and adjust their curves for the presence of solids, pump owners can run into various issues:

- Low production can result, causing financial losses because they’re not producing the tonnage they need.

- System instabilities and subsequent line blockages that stop the movement of slurry through system can cause shutdowns that can cost $60,000 to $200,000 per hour in lost production.

- Reduced flow rates can occur, which could end up blocking pipelines and shutting entire operations down.

“When you’re pumping solids, you do need to derate the pump water performance for presence of those solids,” Furlan said. “If you don’t, you could end up incorrectly predicting where your system is going to operate, and that could cost you a lot of money.”

Lucky for pump owners, they don’t have to manually read water curves or manually adjust for their specific slurry properties.

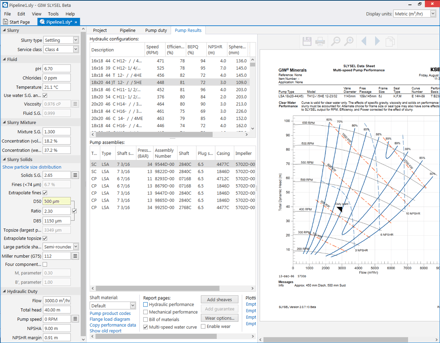

Adjusting for slurries

“You can either do it manually or you can do it using GIW’s pump selection software, SLYSEL” Furlan said. “Doing it in SLYSEL is how it’s done every day at GIW by our applications engineering group because they need to be able to do it quickly and look at a lot of different pumps and slurries in a time-efficient manner. It used to be, decades ago, that pump curves were read and derated manually, but, these days, with the common use of computers and GIW’s SLYSEL software, that isn’t necessary. However, it is helpful if the user of the software understands the concepts of pump curves, what they represent, and how the derates work in order to more effectively select pumps and operate their pumping systems.”

There’s good reason why pump operators should be able to calculate their pump’s slurry performance.

“It’s very important because they need to know where their systems are going to operate,” Furlan explained. “To find out where that slurry system is going to operate, they need to know where the intersection of the slurry head curve for the pump and the slurry head curve for the system is because that defines the flow rate they’re going to operate at and the tonnage that’s going to be going through that system. It’s vital they are able to accurately calculate the slurry performance so that they know what the performance of their system is going to be as well as the effects of varying different parameters.”

And for those having trouble reading and derating their water curves to account for the presence of solids, Furlan and his colleagues offer a solution.

A simple solution

“SLYSEL has various options within the pump duty tab to solve for the pump speed, the pump head, flow, or even impeller diameter for a given set of system inputs or operating conditions,” Furlan said. “So SLYSEL is able to help the user select the right pump and calculate where that pump is going to operate by looking at the problem in a number of different ways.”

“SLYSEL has various options within the pump duty tab to solve for the pump speed, the pump head, flow, or even impeller diameter for a given set of system inputs or operating conditions,” Furlan said. “So SLYSEL is able to help the user select the right pump and calculate where that pump is going to operate by looking at the problem in a number of different ways.”

If GIW customers have questions about their pump’s water performance curves, or about how to derate them to obtain the performance of the pump on slurry, there’s an easy fix for that.

“You would contact us at KSB GIW, Inc., and we would answer any questions you have about the pump curves and solids’ effects on performance.” Furlan explained.

That means expert attention for pump operators who can avoid lost production and downtime affecting their bottom lines — just part of what Furlan enjoys about his role at GIW.

“I think it’s rewarding to be able to help the customers to efficiently operate their systems. It’s important that we’re on-site doing this because it does need to be hands-on in a lot of cases,” Furlan said. “Sometimes you just need to get out there, get the data and samples, and see the actual slurry and operation in order to come up with a real-world solution to a real-world problem.”