One of the best ways to determine a pump’s capabilities is by looking at a pump performance curve. When read properly, this graph can tell you the exact flow rate and pressure at which your pump should be running for maximum efficiency. Combined with a system curve, which takes various flow rates for an entire system into account, you’ll have the most accurate data for determining how to best operate your slurry pump for your system and application.

What’s in a curve?

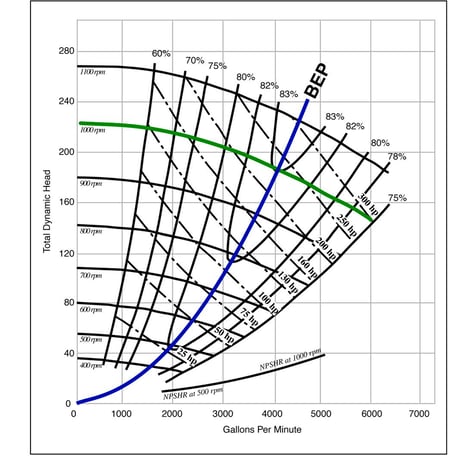

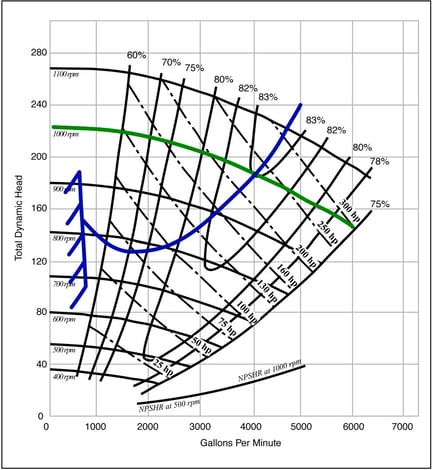

Simply put, a pump performance curve is a graphical representation of the head, or hydraulic pressure, the pump produces for various flow rates at a given speed. As the flow rate increases, the head always decreases — and somewhere along this curve, you’ll find the best efficiency point (BEP) that identifies the specific flow rate at which you’ll achieve maximum efficiency.

A complete performance curve array also includes data about the head produced over a range of capacities, power necessary to create a certain flow and head, efficiency ratio of energy transferred to energy required, and the required net positive suction head (NPSH).

It’s a lot of valuable information in one graph! If you’re really interested in delving into how your pump impacts the performance of your entire slurry operation, it’s only a portion of the data you’ll need.

A pump always operates best at its duty point — the point where the system curve intersects with the pump performance curve. The system curve is another high-value graphical tool, which represents the energy, or head, required to move slurry through a piping system.

Getting the most out of your pump curve

Together, these graphs provide the best cost- and time-saving insights into your pump and pumping system. The trick is figuring out how to read these curves in accordance with your unique application.

It’s important to keep in mind that pump and system performance prediction is challenging. This, in part, is because all pump curve data is based on testing with clear water. So, depending on what kind of slurry you’re pumping, operators will need to adjust.

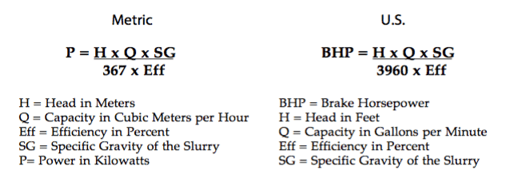

However, there is a basic formula for determining the power necessary to operate your pump. You can calculate this by applying one of the following formulas to the data from your pump’s performance curve:

Digging deeper

While this will give you a tangible estimate for power and help you get the most out of reading your pump performance curve, as previously mentioned, you may need to make some modifications depending on what you’re pumping through your system.

That’s where slurry pump professionals come in. Experts develop performance and system curves through intensive research and observation. In fact, pump curves can be certified only through full-size performance testing in accordance with Hydraulic Institute Standards in an approved laboratory.

With sophisticated computer models, years of experience, and state-of-the-art testing facilities, experts can help ensure you get accurate pump performance and system curves for any pump in any application. Without this insight, operators can face years of frustrating — and expensive — issues.