If you’re an experienced slurry pump operator, you’re aware of some of the reasons for high rates of pump wear — which can negatively affect pump performance over time. Although slurry characteristics such as particle size and concentration may first come to mind, an..

Read MoreSlurry Pumps and Oil Sands Blog

Few spaces in the slurry pumping industry are as innovative and well-known as GIW Industries Inc.’s Hydraulic Lab. This large-scale testing facility is equipped for testing pump performance and optimizing slurry systems. Of course, this state-of-the art laboratory benefits GIW’s..

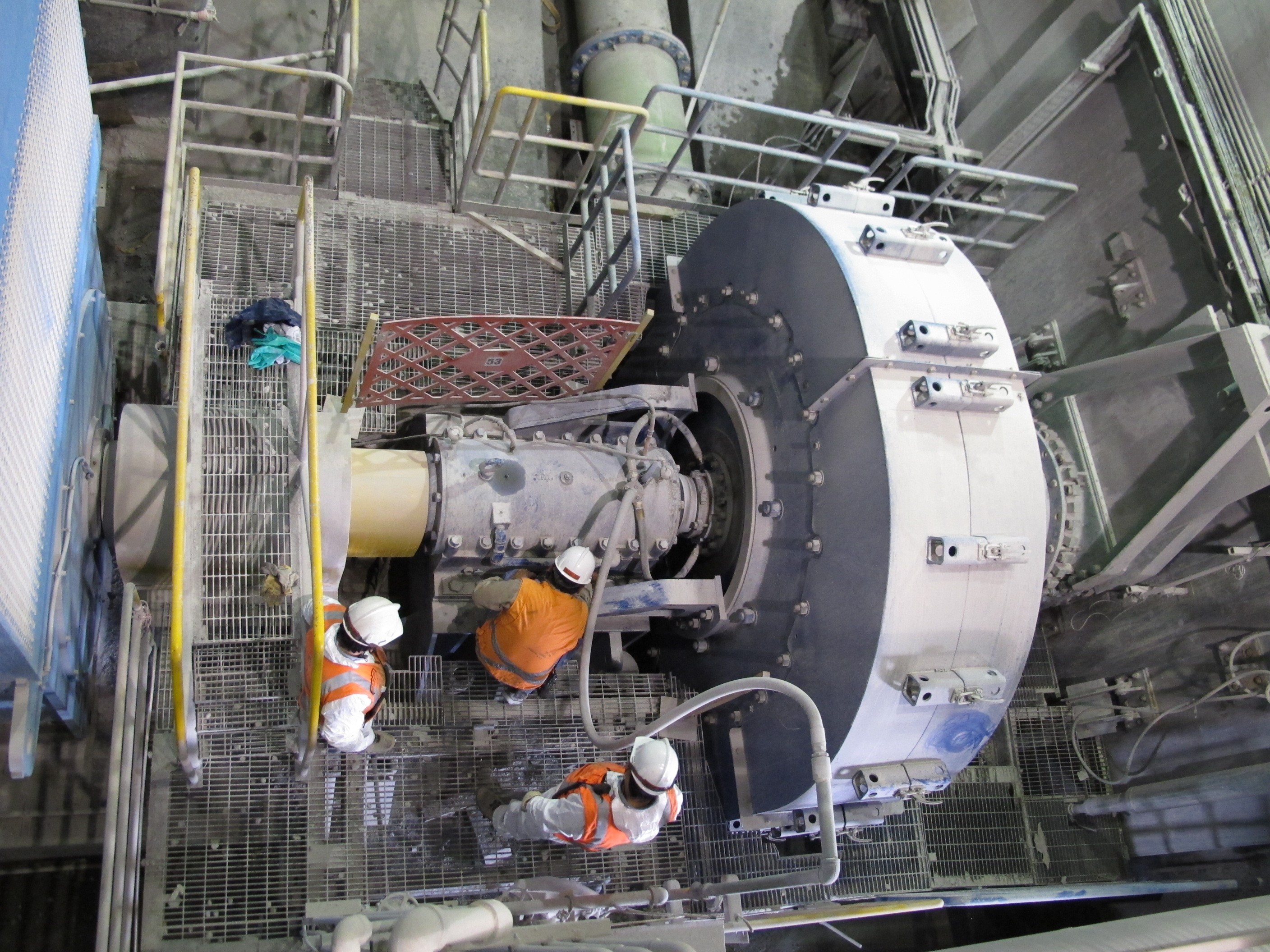

Read MoreLike so many other machines, slurry pumps require regular maintenance to function optimally and reliably. Without proper care, pumps can suffer catastrophic failures, which can result in unscheduled repairs, potential injury, and facility downtime. Even if they don’t fail,..

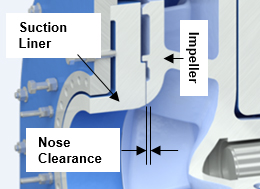

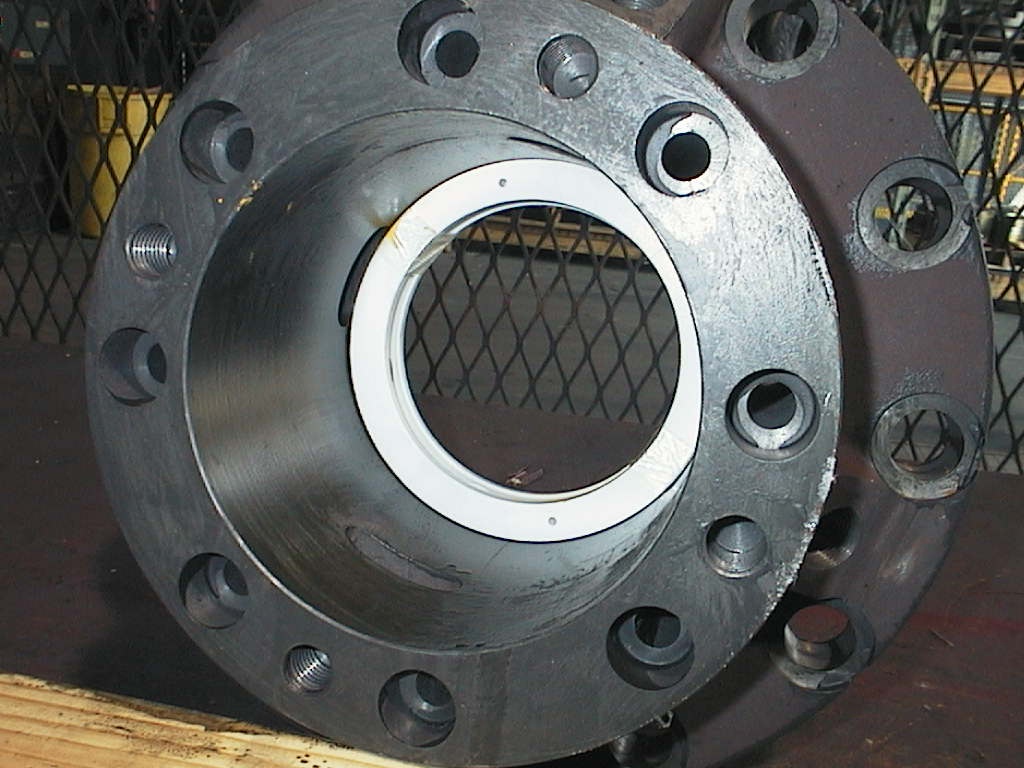

Read MoreQ: Our pump is running fine. Why did our KSB GIW, Inc. representative tell us we need to adjust our pump’s nose gap?

Read MoreTopics: Tech Tips, GIW, Oil Sands, Slurry Pump, Pump Basics

Equipment retention is a critical aspect in maintaining any piece of machinery. But knowing the right steps and the right tools you need to keep your equipment functioning properly can get tricky. When it comes to centrifugal slurry pump maintenance, a stuffing box is the best..

Read MoreTopics: Tech Tips, GIW, Oil Sands, Slurry Pump

Winter is coming; are your pumps ready? Here are the steps you should take to ensure your pumps are primed for even the harshest conditions.

Read MoreTopics: Tech Tips, GIW, Oil Sands, Slurry Pump