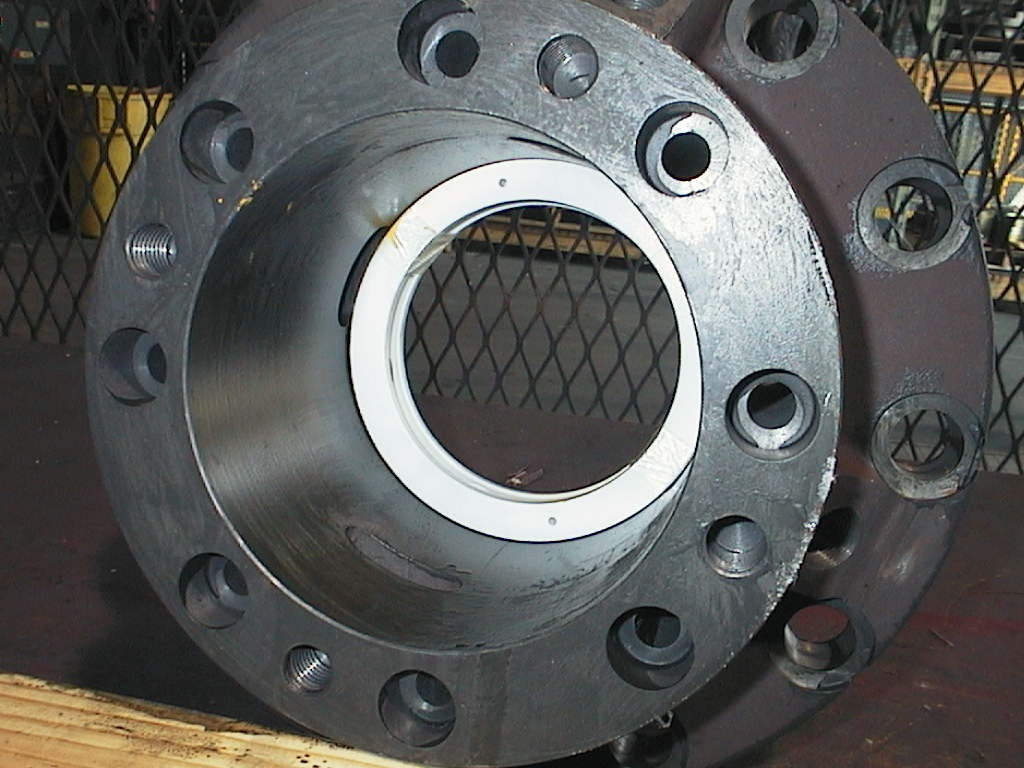

Equipment retention is a critical aspect in maintaining any piece of machinery. But knowing the right steps and the right tools you need to keep your equipment functioning properly can get tricky. When it comes to centrifugal slurry pump maintenance, a stuffing box is the best option for time-sensitive issues that may arise. A stuffing box separates the non-rotating parts from those that rotate. It is a reliable option to hold your packing seals and shaft as well as keep your pumping system from leaking. The importance of knowing the proper cleaning and packing procedures becomes evident during a shutdown event when you need to keep your pump running efficiently.

KSB GIW, Inc. Southern Region Manager and slurry pump expert Angela Bryant talked us through how to properly pack a stuffing box.

- Inspect. “One of the first things you want to do once you’ve disassembled it is take the parts and inspect them to make sure there is no grooving, sharp burrs, or excessive wear in the area of the parts that you’re removing,” Bryant said.

- Align. “After you’ve gone through inspecting the parts, you want to check to make sure the stuffing box ID is concentric by taking a centering device, telescopic bore gauge, or micrometer and measuring in four places: 12, 3, 6, and 9,” Bryant said. “What that’s doing is allowing you to align it with the shaft sleeve. If you don’t have a centering device or telescopic bore gauge, you can take a shaft sleeve and center it along with a piece of packing to see if it’s centering up correctly.”

- Install lantern rings. “Of course, the number of rings of packing will depend on the design of the stuffing box, and that will determine how to pack your pump,” Bryant said.

KSB GIW, Inc. offers two types of stuffing boxes as well as replacement parts for a third type, which makes choosing the proper lantern rings and packing of utmost importance. Be careful not to pack for the wrong type!

- KE designs are best for minimum water usage and require one or two packing rings ahead of the lantern ring. In this model, the lantern ring aligns with the gland port with two to three pieces of packing behind.

- The throat bushing design, the design Bryant recommends most often, replaces the forward piece of packing on a stuffing box. It’s a variation of a bushing piece and a piece that replicates the forward piece of packing with a lantern ring and a bushing. It produces a throttle effect that lightly restricts water flow. It has a little bit longer lantern ring design, making it important to align the throat bushing’s lantern ring with the gland port to avoid failure. This style is easier for maintaining in the field as it’s not necessary to pull the throat bushing out unless it’s damaged, and there’s no forward piece of packing.

- Forward flush designs, although phased out due to excess water usage, are still used where gland water supply is plentiful and it’s not necessary to worry about process flow dilution. While GIW doesn’t supply forward flush designs on new pumps, operators in the field still use them and GIW still supports and services them.

- Pack and tighten. Once you know what style lantern ring or throat bushing is being used, you’ll know the number of packing rings required. The next step is to ensure each packing ring is cut to the correct length prior to installation. Once verified, it’s time to install the stuffing box packing rings. KSB GIW, Inc. sells these prepackaged and precut with angled ends, which ensures they’re the correct length based on the shaft size and makes for easier installation. If packing is cut too short or too long, it can lead to premature failure.

When packing, ensure you stagger the joints so they are not in alignment and the last piece is at the six o’clock position. Firmly seat each of those rings with a suitable tamping tool. If you find tightness when installing packing, you can use a 2- to 3-inch-long piece of PVC pipe cut in half to tap packing into place. Another option is to use a lubricant on the underside of the packing to help it slide into place. Then, install and tighten the two-piece gland and compress the packing into the stuffing box. When you first tighten it up, you don’t want to overtighten. Once compressed, back the gland away to release any pressure off the packing. Then, finger-tighten the glands onto the packing.

“Finger-tightening is the key word so you don’t overtighten the packing, which can possibly burn during startup. It can glaze the bottom side of the packing and would not allow for the packing to seal correctly,” Bryant said. “You’d have to go back in and reinstall if you do that.”

That could make for a lot of rework! And Bryant has seen it firsthand.

“I’ve actually been in a plant when the guys installing [the gland] tightened it up too tight,” Bryant said. “The whole building filled with smoke, and they had to put additional water on the stuffing box to cool it down for 24 hours before it stopped heating up. By then, they’d already glazed the packing, so it was never going to seal.” - Apply seal water. “Once you’ve tightened the glands, the seal water should be applied right before you start the pump up. If there’s no leakage coming out at that point, the packing could be too tight,” Bryant said. “You want to loosen it up just a little so you have water coming through.”

Once you start up the pump, look for leakage. Let it run for about an hour or so, allowing the seal water to saturate the packing so it seals correctly. Then, tighten the gland so a pencil-sized stream of cool water flows through.

“It can be kind of warm to the touch, and you want it clear,” Bryant said. “If it’s hot and cloudy, you need to loosen the gland studs up a little.”

With an open-end wrench, tighten it one side at a time so you don’t overdo it. - Check the flush water requirements. “In most cases, this is going to be dependent upon the discharge pressure. Check the discharge gauge to see what the pressure is, then add 10 PSI above that,” Bryant said.

For example, if your discharge pressure gauge reads 75 PSI, you’ll want 85 PSI of pressure on the gland water line.

Recommended flow rates are also available in KSB GIW, Inc. pump manuals, allowing pump owners and operators to understand their flow rates by gallons per minute instead of by pressure.

After that, you’re ready to go! A properly packed stuffing box can help you reduce operating costs by avoiding high water and power costs. It can also help you steer clear of the shaft sleeve wear leakage can cause. Prolong your packing and shaft sleeve life while you protect against unexpected shutdowns and failures. Pack properly to extend the life of your pump — and keep your bottom line strong!