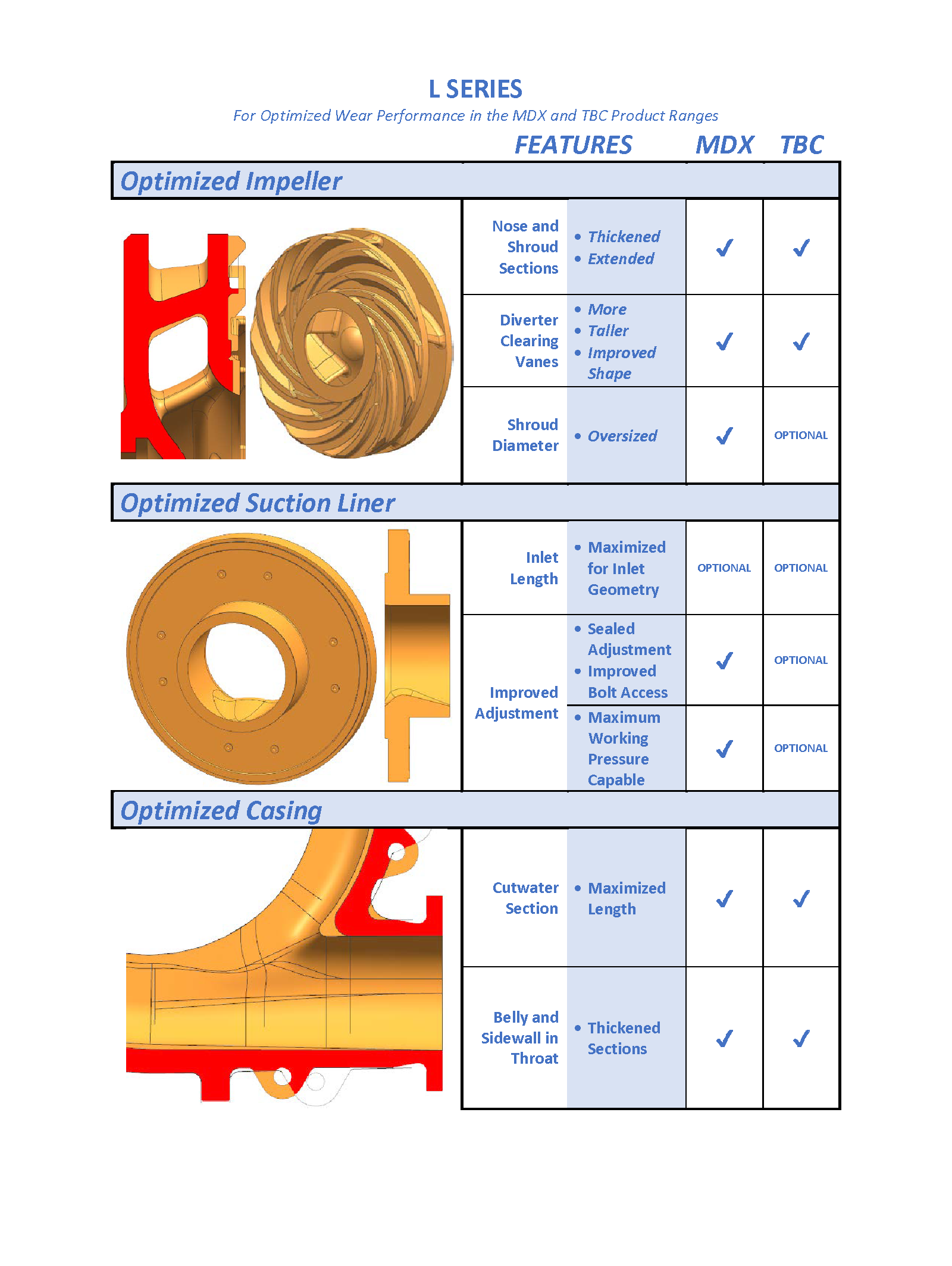

In a continuous effort to improve the wear life of KSB's mill duty and hydrotransport/tailings pumps, the L Series of MDX and TBC pumps has been developed with features designed to significantly extend wear performance with minimal impact to hydraulic performance. This has been accomplished by applying small but impactful design changes to specific areas within the pump known for aggressive and accelerated wear, while maintaining the proven hydraulics and wear technology inherent to the MDX and TBC ranges, which have already set a high bar for service life in the most severe applications.

These changes have already been implemented with great success to meet ambitious wear improvement targets set forth by customers in Mill Duty applications on the MDX-400, MDX-500, MDX-550, and MDX-600 product lines respectively, as well as applications in hydrotransport on the 24X28 TBC-67 product line. The upgrade is planned or already available for all MDX sizes from MDX-400 to MDX-850, and TBC sizes from 18X20 TBC-58 to 30X34 TBC-92.

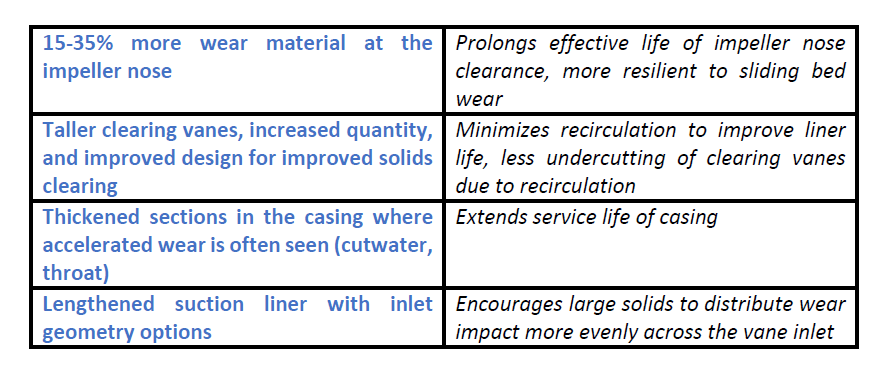

Hydraulic performance testing between the previous MDX/TBC designs and their L Series variants have thus far proven the intent of negligible impact to hydraulic performance parameters, including head, efficiency, best efficiency flow, and NPSHR. The primary effect of the change is a significant improvement in service life of the impeller and suction liner in service (as much as 40%). By increasing the critical nose thickness on the impeller and improving the quantity, height, and shape of clearing vanes on the suction shroud, recirculation is minimized, and the nose clearance is maintained over a longer period of time.

These improvements, when coupled with regular nose clearance adjustments, help delay the onset of gouging wear patterns and can prolong the life of these critical parts significantly. The longer bore of the suction liner also lends itself to the immediate or subsequent inclusion of inlet geometry intended to counter the effects of sliding bed wear common with low flowrates or large particle sizes, with no change to the suction spool size or location. To summarize the hydraulic and feature enhancements available with the L Series of MDX and TBC pumps:

KSB is excited to bring these L Series features and enhancements to new applications, as well as TBC and MDX pumps already in the field, as we share our success with our clients in the form of prolonged run time and increased time between outages.