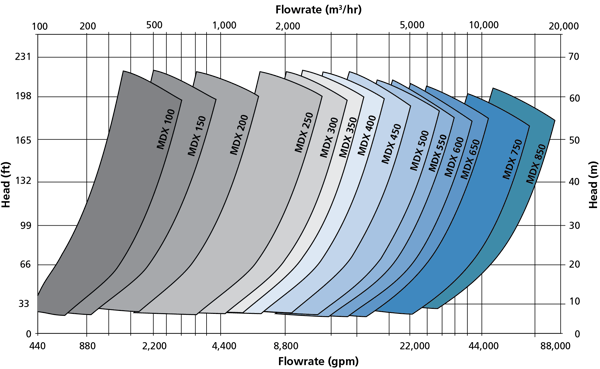

KSB’s line of GIW® slurry pumps are designed to handle critical customer applications in hard rock mining. The GIW® Mill Duty Extra Heavy (MDX) product line is capable of handling the most extreme mill conditions. The key features of the MDX product line work together to offer head, flow, and efficiency critical to a productive mill operation.

Mining operators are experiencing increased demand for minerals and ore. As KSB GIW, Inc. customers sought to increase production, the need for a mill duty pump larger than the MDX-750 was clear.

The MDX-850 is the newest and largest addition to this already impressive line of pumps.

Meet the MDX-850

The MDX-850 is a major step up in size from the MDX-750. The MDX-850 is now the largest hard rock pump that KSB produces with an 850 mm (34 in.) discharge, 2,600 mm (102.3 in.) impeller. It’s intended for mill duty applications and optimized for severe duty service class four slurries at heads up to 40 m and flows as high as 16,000 m3/hr. and class three slurries at heads up to 55 m and flows as high as 18,500 m3/hr.

KSB estimates the MDX-850 has the highest BEPQ (Best Efficiency Point Flow) of any pump currently on the market for similar applications. With its unmatched capacity and wear performance in class four service, this pump sets a new standard for mill duty slurry pumps in hard rock mining and boasts ideal hydraulic and casting designs. The sizing also contributes to the ease of pump maintenance — a source of pride in the design of KSB GIW, Inc. pumps.

Design features of the MDX-850 also include a variety of improvements applied to the MDX range in recent years, such as an increased pump width to allow for improved diverter design, and a thickness increase in critical areas of the impeller to improve operation and wear life. Thickened impeller vanes, cast in proprietary materials Gasite™ 28G and Endurasite™, improve wear life, so the lifecycles of wet-end parts match scheduled downtime.

The MDX-850 features an improved interface between the suction liner and the suction plate, which allows for the use of a wear ring and innovative hydraulic features at the pump inlet. As with all GIW® MDX pump assemblies, the MDX-850 has an adjustable suction liner. The MDX-850 is compatible with the GIW® RAMSL (remotely adjusted mechanical suction liner). RAMSL technology makes for faster and more accurate nose gap adjustments.

Applications and advantages

KSB designs pumps with our customers in mind — meeting their needs and helping them improve their productivity and efficiency — and the MDX-850 is no different.

According to Amy Lewis, KSB’s MDX-850 Product Manager, “A significant amount of time and attention was devoted to the impeller hydraulics to ensure they would offer the best performance.” The impeller vanes are designed with a goal of improved wear life. This allows for the life cycle of all wet-end parts to match in order to streamline maintenance and minimize potential downtime. Genuine OEM replacement parts are essential to maximizing machinery wear life. Both standard sealing options utilize packing and are low flow to aid in water conservation. The MDX-850 is a metric pump with metric taps and hardware. It is designed with a full pump lift in mind and includes lift points on the pump assembly’s suction plate and pedestal. The hub plate and pedestal feet are at the same elevation to simplify maintenance work onsite.

The MDX-850 design is compatible with the GIW® RAMSL technology upgrade, so customers have the option to make their maintenance program even more efficient with a state-of-the-art digitally enabled suction liner adjustment system. RAMSL allows for remote nose gap adjustments and monitoring. One engineer can adjust the suction liner in a pump remotely, with a precision of 0.25 mm, at the touch of a button on a control panel.

KSB is proud to work with current and potential customers to offer the best solution for their specific needs. The MDX-850 is well-suited for grinding circuits, SAG and ball mill discharge, and cyclone feed applications. The MDX continues to be the top choice for mill circuit pumps, and the 850 promises to shatter current barriers to mill production.