A gasket is just a gasket, right? It’s just a ring that sits next to the impeller.

So why do KSB GIW, Inc. gaskets have notches in them?

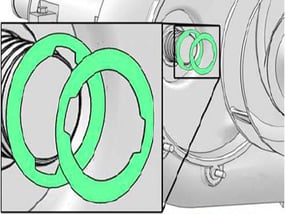

The simple answer is that the notches allow the gasket to stay centered and fit snugly into the shaft threads. This fit is an essential feature because GIW recommends using not one, but two shaft sleeve gaskets to make the impeller easier to remove when it’s time for maintenance.

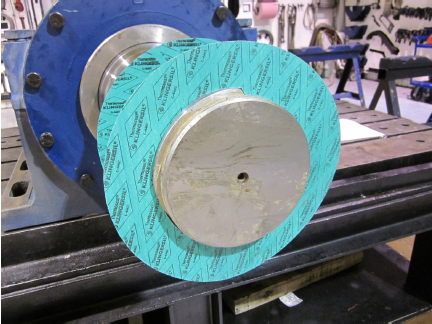

Gasket with two notches |

Notches allow gaskets to screw onto shaft threads |

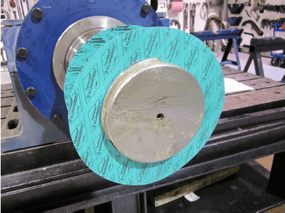

Staggered Gaskets |

Centered Gaskets |

Follow these steps to use the gasket notches effectively and make your maintenance job easier:

- Start with clean, dry gaskets. You may coat the shaft threads with anti-seize compound, but do not lubricate the gaskets.

- Always use two gaskets to ensure future impeller removal is easy. (Get tips for removing a stuck impeller here.)

- When threading the gaskets onto the shaft sleeve, change the starting position of the notches on the second gasket so the notches on the two gaskets don’t line up and leave a gap after they are fitted.

When your gaskets are installed properly, they will be neatly centered behind the shaft threads, ready for installation of the impeller.