KSB has a long history of partnering with customers to offer the best solution for specific application needs. With many challenges universal throughout the mining industry, KSB is always incorporating new knowledge into new product solutions.

Mollie Timmerman has more on this history of customer collaboration — and the new GIW® Tailings Dewatering (TDW) line of pumps set to define the future of tailings management.

KSB is known for innovating to meet specific customer needs. Is that what happened with the TDW line?

The TDW product line was based on the success of the WBC-54 expeller pump in the field. We noticed an increased demand for pumps with waterless seals, or seals that do not require gland water. There was also a need for larger pumps compared to what we had available at the time. So, the TDW was introduced to bridge the gap between the LCC expeller range, which features an expeller seal as standard, up to a 28-inch impeller, and the WBC-54 expeller pump, which is a 54-inch impeller. It also provides some additional capability to extend the product range even beyond the capabilities of the WBC-54.

What is the process for a collaborative project like this?

In this instance, we were receiving many one-off quotes from customers requesting expeller-type solutions or waterless seals. We put our heads together as a company — sales, product management, engineering, applications engineering — and saw that with this number of requests, perhaps it was best to address this via a product line development versus continuing to handle them as one-off requests. And that's essentially how the TDW was developed. We saw there was a range of pump sizes needed, and attacking this via a new product line introduction made the most sense.

Mollie Timmerman

Mollie Timmerman

The customer was heavily involved with the development of the WBC-54 expeller, and much of that development work, features, and benefits carry over to the TDW product line. There was probably less direct customer involvement because it was a strategic approach, but it did develop from a specific customer need on a previous project where the customer was highly involved.

How do TDW pumps improve the dewatering process?

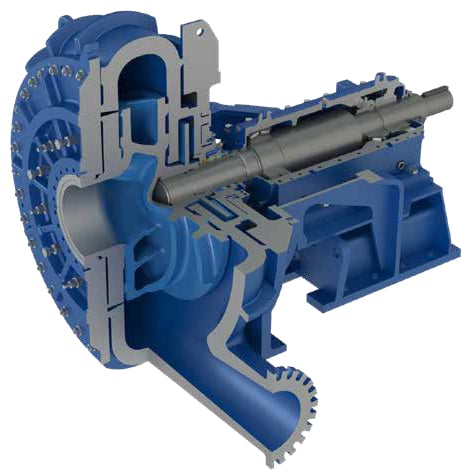

The TDW is a tailor-made design for tailings pond dewatering, just as its name implies. It provides a wider range of flow capability and is capable of high head operation. Because it does not require gland seal water, it's a sustainable option. It is very costly to provide gland water to remote tailings locations, so utilizing a proven waterless seal solution like the expeller is highly beneficial. The wet end is constructed from GIW’s Gasite® — a high-chromium white iron alloy material that provides outstanding resistance to abrasion/erosion, corrosion, and impact. The robust mechanical end is designed for slurry service, which reduces complexity and is easier for service and maintenance. The TDW also features an adjustable suction liner and is capable of being lifted as a single unit. All-in-all, the TDW is designed to offer a low total cost of ownership by reducing operating costs, requiring less maintenance, and providing a long run time.

Gasite

Gasite

How does the TDW line contribute to a mining operation’s sustainability?

The main point is that the TDW does not require gland seal water. Gland seal water does not need to be made available, which is a big savings for the mining operation. And it's more environmentally sustainable because gland water does not need to be trucked into the mine or subjected to additional filtering and cleaning processes.

What types of equipment can the TDW optimize and how?

Typically, the TDW will be used wherever tailings need to be moved. Most commonly the TDW will be used on a dredge, barge, or pump skid. It can replace traditional pumps that have gland packing and require gland water. The main benefit of the TDW is the fact that it doesn't require gland water. It can even be used in place of existing pumps that do require gland water, so field retrofits are possible as well.

Are there any other benefits to the customer you’d like to highlight?

Because it is a robust slurry pump, it will require less frequent maintenance. The fact that it can be lifted as a complete unit makes it easier to service. For example, the customer might choose not to service the pump on the barge. They might prefer to remove the entire pump from the barge and transport it to a land-based service shop. So, being able to move the pump as one assembly versus disassembling and reassembling it is a maintenance friendly feature. With the GIW Gasite® wet end construction, the pump is designed for the long run — for extended run times — which contributes to lower total cost of ownership and lower operating costs.

What do you think a sustainable approach to tailings dewatering does for a company beyond the immediate on the ground benefits?

I think it demonstrates forward thinking in the willingness to implement different technology on a pump, or in looking for ways to do business that are different from how business has been done in the past. It’s taking a holistic view to the mining market and making sure we’re conducting sustainable business to support future generations, and we're doing our best to continuously innovate ways to make that happen.

GIW® TDW - Tailings Dewatering Pump

GIW® TDW - Tailings Dewatering Pump

You talk about the TDW being a result of the WBC-54. Do you think the TDW will be a jumping-off point for other potential projects?

Perhaps. The TDW was developed for tailings dewatering, which is light- to medium-duty slurry, and I think where the interest lies in terms of taking this further is to see what type of waterless seals could be offered for a more severe slurry duty. It's something that doesn't exist in the market today, and it’s raised in discussions for applications that have traditionally been very gland seal water dependent — what options are available for severe duty waterless seals?

What’s the next step for the TDW line?

Currently we’re processing an order for the TDW-600, which will deliver to the customer in early 2023. We’re looking forward to not only the success of the WBC-54 expeller, but the success of the TDW 600 — which has a 57-inch impeller — and experiencing further growth of the TDW product line.

In the oil sands industry, there remains a lot of focus on dewatering tailings ponds and the need to move between ponds as they fill. So, for the time being, there's certainly going to be increased demand for a tailings-related pump and having a solution that doesn't require gland water.

How does KSB move from, “Let’s solve this customer’s specific challenge,” to, “This is a universal problem? Let’s create a new pump line”?

As opposed to making a lot of one-off solutions, we're shifting our focus and taking the approach of asking ourselves “How can we apply what might be asked for as a one-off solution, and get a strategic approach?” It’s a matter of applying this approach across the range of market needs to make a strategic product development decision. Based on my experience, if there is a problem in the field that requires a solution, the KSB Mining team will put our best efforts at working with the customer to find a solution.

And generally, if a solution can be made, and it makes sense for the customer, we will figure out a way to make it happen. We demonstrate a strong spirit of innovation and continuous improvement.

Continuous improvement is a bit of a buzzword lately, but it’s been KSB’s theme from the beginning, correct?

Yes, especially as a slurry pump provider. Providing slurry pumps to mines is not a business where you deliver a product, wash your hands of it, and walk away. When that product delivers, and it's installed and operating, it's a new phase of the business relationship because that equipment can be in service for 20 years or more and at some point, it's going to need support. The KSB Mining team needs to be present to support the product and help the customer through both the good times and the challenging times.

Is there anything else you’d like to share?

We strongly encourage our customers to reach out to us for expeller solutions. Don't be shy. We have years of application and operating experience, and we're eager to bring that knowledge to the field and discuss with operators how we can improve their operations, save them money, and bring additional value.