If you own or have ever seen an older pump’s bearing assembly, you’re probably familiar with the old oil breather. If this is the case, you may be surprised or confused when you see a KSB GIW, Inc. pump that doesn’t have one.

That’s because GIW bearing assemblies no longer require oil breathers. They were replaced decades ago in favor of cleaner, more efficient technology — and you should avoid them, too.

Oil breathers can harm new pumps

Prior to the 1980s, oil breathers were an important component of GIW’s pump bearing assemblies that featured lip seal and Taconite seal end cover designs; however, those old sealing technologies are now obsolete and most have been — or should have been — replaced.

Although GIW’s original pumps featured oil breathers, the new ones don’t require them. In fact, not only do new pumps not need the breathers, their use can actually harm the pump.

“Oil breathers provide a way to get contamination into a pump,” Jon Keith, KSB GIW, Inc.'s resident slurry pump expert, says. “Most GIW pumps are used in harsh environments and are constantly being sprayed with slurry or washed down with water. If someone were to spray water from a hose directly onto the air breather — unless it’s a special one designed to repel water — it could force water and debris into the bearing housing, thereby causing subsequent oil and bearing contamination. The breather can also draw dirt particles into the bearing housing as it naturally expands and contracts.”

We have newer, better technology

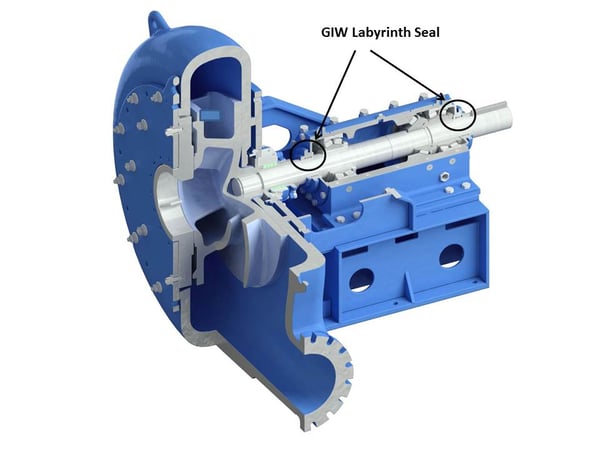

In place of oil breathers and lip seals, GIW’s standard bearing end covers are now a labyrinth seal design.

“The labyrinth seal end cover handles excessive oil splash from the inside of the bearing housing and prevents foreign materials from entering from the outside,” Mr. Keith explains. “It also allows for natural ventilation by allowing air to flow in and out through the end cover; therefore, there is no longer a need for a breather.”

Because GIW has eliminated the use of breathers on the majority of its pumps’ bearing assemblies, any damage or failure to the bearing assemblies due to the aftermarket addition of an oil breather could become the customer’s responsibility.

“If you add a breather, it’s just another way to let debris in,” Mr. Keith says. “You’re just asking for trouble and contamination!”

Need a hand with your pump bearing assemblies? GIW Tech Services experts can help. To see a list of all our offerings and how they can benefit you, check out our GIW Service Centers brochure.

Need a hand with your pump bearing assemblies? GIW Tech Services experts can help. To see a list of all our offerings and how they can benefit you, check out our GIW Service Centers brochure.