To answer this question, we spoke with Reab Berry, former Head of Global Mining Training and Development for KSB GIW, Inc.

“There’s a particle size that’s well-known in the slurry transport industry as the Murphian particle size,” Mr. Berry says. “In the world of slurry pumping, it is — without a doubt — a very difficult particle to pump.”

The perfect particle to pose a problem

What makes this 500-micron particle such a challenge for slurry pumping experts around the globe?

As Mr. Berry explains, the Murphian particle is the perfect size to get stuck in the boundary layer that exists inside all slurry pipelines.

“There’s a boundary layer around the inside of pipe that happens to be about 500 microns thick, and the Murphian particle gets trapped in that layer,” Mr. Berry says. “It’s too small to stick up out of the boundary layer and get pushed along by brute force, and it’s too large to get kicked up out of the boundary layer into turbulent suspension like particles smaller than 500 microns, so it just gets trapped.”

To better understand how this happens, take a look at the KSB GIW, Inc.-produced video that shows how Murphian particles can cause difficulty in slurry transport pipelines:

Finding a solution

Clearly, Murphian particles can present significant problems in pipelines. Luckily, you can adjust the transport velocity to avoid these issues.

So, how do you know what velocity to use if you pump significant amounts of this 500-micron material?

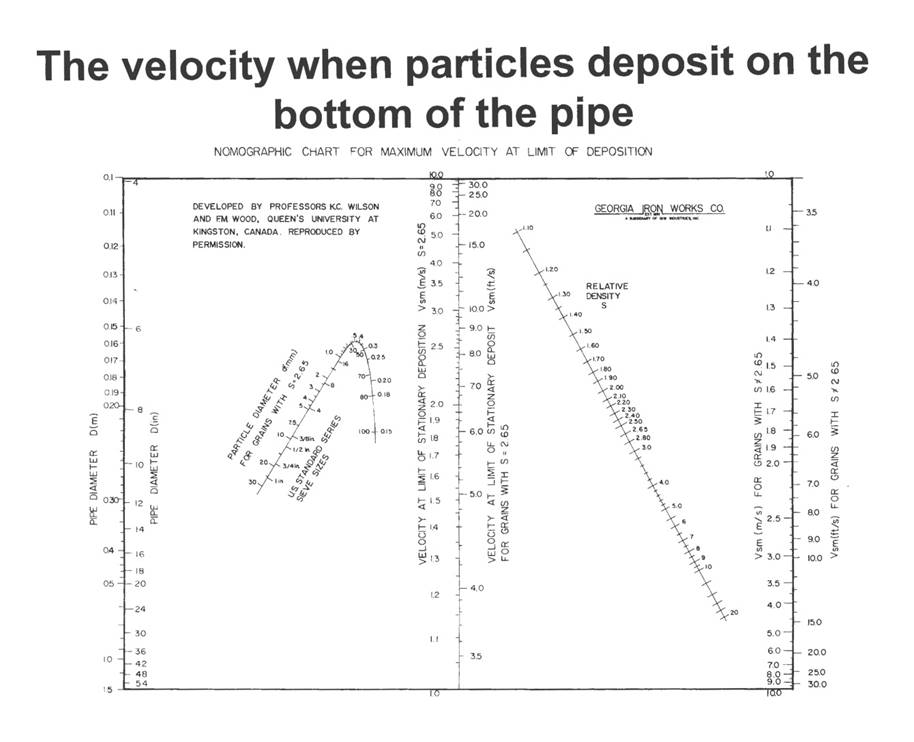

That’s where Wilson’s Deposition Velocity Nomogram comes in handy:

“This chart is a standard for slurry transport,” Mr. Berry says. “It’s very simple: You can determine the transport velocity for different particle sizes in any size pipeline using this nomographic chart.”

Want to learn more?

While this chart is remarkably helpful for slurry professionals struggling with the Murphian particle, many are interested in learning more about this difficult — and sometimes counterintuitive — pumping concept. If you’d like more information, we encourage you to take part in our annual Slurry Transport Course.

“For the slurry transport mechanisms that cause the Murphian particle to be so difficult to pump, you can come to KSB GIW, Inc.’s five-day seminar we give once a year,” Mr. Berry says.

And you’ll also gain a wealth of other knowledge from this prestigious, hands-on slurry transport course.

Mr. Berry says, “We’ve been doing it for 40-plus years, and you can learn everything about slurry transport you’ve ever wanted to know — and maybe more!”