.jpg?width=900&height=506&name=WBC%20Blog%20Photo%20(1).jpg)

In 2020, United States based company Mike Hooks, LLC was experiencing less than optimal performance from a pump on the cutter suction dredge E Stroud. The company reached out to KSB GIW, Inc. representative, Hagler Systems, to resolve the issue.

Challenge

The dredge E Stroud had one pump that was installed by a competitor. This pump had become unreliable due to extreme wear resulting in increased and unplanned downtime. The dredger was also experiencing major issues with the shaft seal causing safety risks that included excessive amounts of standing water in the hull. Aside from these challenges, it was also difficult for the company to acquire the replacement parts in a timely manner; thus, jeopardizing on-time completion of dredging projects.

Solution

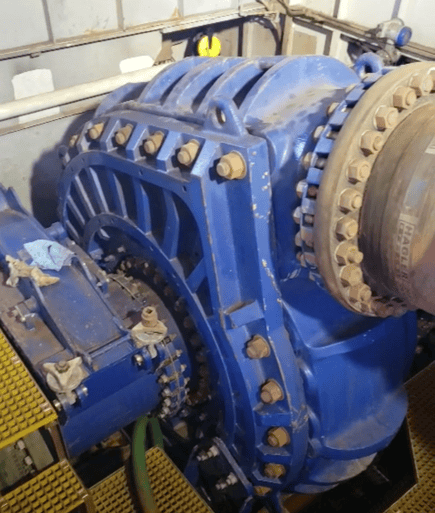

The Hagler Systems team reviewed the production goals of the company, conducted research on similar dredging applications, and discussed the project with Application Engineers at KSB GIW, Inc. Together they concluded that the GIW® WBC-64 with a Liquidyne® shaft seal would be the best solution. Upon making the recommendation, the Mike Hooks group made a special request to enlarge the pump discharge. GIW customized the casing to augment the discharge by two inches.

To prepare for the retrofit, Hagler Systems conducted a customer site visit to measure the dredger pump layout. The measurements were used to develop adequate design bases, cleanouts and other auxiliary components. This allowed Mike Hooks to replace the third party dredge pump with thebest in class GIW® WBC-64 dredge in an efficient manner.

Results

The retrofit of the WBC-64 with the Liquidyne® shaft seal, exceeded the performance expectations outlined by Mike Hooks, LLC. The pump realized the following results:

• Surpassed the company’s production goal and increased production by 50%.

• Eliminated shaft seal leakage and maintained a dry hull.

• Improved overall wear on the components and reduced down time.

The success of the project resulted in Mike Hooks purchasing two WBC-64 pumps for their new Lorraine cutter dredge project.